STAMPING

Metal stamping can quickly and cleanly create solid metal parts and forms. This process uses specialized dies that press sheets of metal into precisely the right form. Metal stamping techniques can handle a variety of metals, which allows us a degree of flexibility without additional costs.

Our machinery process involves the use of mechanical presses, which have a mechanical flywheel powered by a motor.

Jay & B Tech maneuvers 110 -500 tonne Mechanical Power Press Machines.

We also operate five N.C Leveller Feeders with capacities of coil width and coil weight ranging between 80 ~ 500 and 4 tonne respectively.

SPOT WELDING

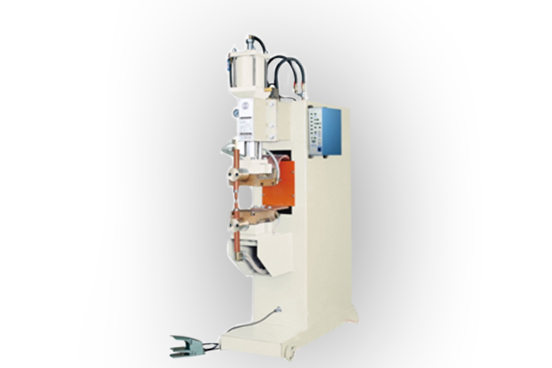

Spot Welders are designed for extra ordinary versatility and are available with different styles of welding head arrangements.

These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and rotary movements with PLC could be supplied for fast production.

Our spot welding machine is from Autoweld India Technology Pvt Ltd; original equipment manufacturing from Korea carrying a 100 KVA capacity with specialised nut auto feeding.

ROBOT WELDING

Typically equipped with six axes per robot, industrial robots provide the versatility needed to perform a plethora of applications.

From welding to material handling, from dispensing to material removal, these robots are fast and efficient, improving operational productivity.

Jay & B Tech strives to be up to date with the current technology to provide high end services as per clients’ stating. We are using Robot welder- AR1440 that boasts a MS copper coated coil wire diameter ranging between 0.8 – 1.2

Zn PLATING

Zinc plating is one of the most prevalent applications of electroplating. Its core purpose is to deliver a protective coating to metal accessories such as fasteners, bolts, nuts, and automotive parts. Zinc provides an insulating surface over the iron and steel from corrosion.

It can also enhance the appearance of metal components by giving them the desired color and brightness with an elegant shine.

ED COATING

ED stands for Electrophoretic Deposition. Electro-coating / ED coating is a process by which electrically charged particles are deposited out of a water suspension to coat a conductive part. During the electro-coating process, paint is applied to a part at a certain film thickness, which is regulated by the amount of voltage applied. The deposition is self-limiting and slows down as the applied coating electrically insulates the part.

Electro-coated solids initially deposit in the areas closest to the counter electrode and as these areas become insulated to current, solids are forced into more recessed bare metal areas to provide complete coverage. This phenomenon is known as throw power and is a critical aspect of the electro coat process.

BRAKE SHOE MANUFACTURING

PROJECTION WELDING (SPM)

This projection welding machine is specially designed for welding brake shoe assemblies.

The machine is equipped with basic welding controls including Transformer, Microprocessor based control, pneumatically actuated vertical welding head and special rotary indexing fixture with drives.

KNURLING

Knurling is a finishing process that develops a texture on the given work piece. The main reason for knurling is to create a surface finish that will enhance grip.

The knurling application can also be used so that serrated edges of work pieces are locked and keyed together to form a unit.

SHOT BLASTING

Shot blasting is a method used to clean, strengthen (peen) or polish metal. It is an aggressive pre-treatment process that involves propelling small abrasive particles at metal surfaces.

It makes it much easier to coat metal objects more effectively, ensuring that the coating you apply adheres effectively to the metal surface.

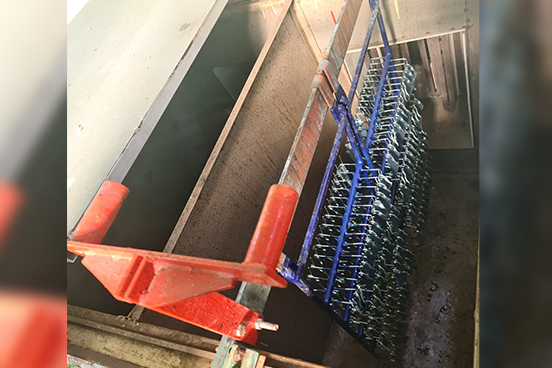

WELDED SHOE WASHING

The brake shoe is cleaned using Industrial grade solvent that acts as an aid to degrease or further clean the brake shoe.

The solvent is heated to a desired temperature and the brake shoes are washed through the precipitated fumes.

WELDED SHOE GLUE DIPPING

A step of dipping the brake shoe in a chemical conversion coating for the process of bonding.

BRAKE SHOE BONDING

During the bonding operation the coated lining and brake parts are positioned together under pressure and heated to fuse and cure the adhesive layer.

The pressure must be maintained in order to prevent bubbling of the adhesive as volatile products are released during the curing.

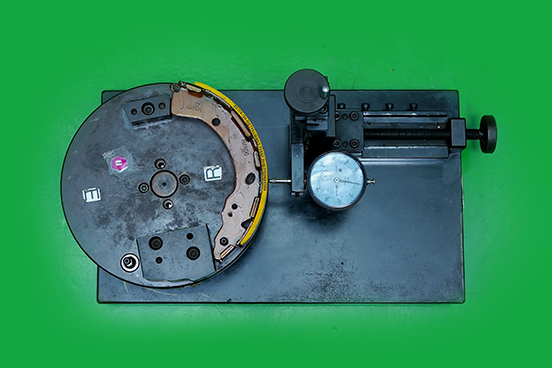

BRAKE SHOE GRINDING

A further step of grinding / chamfering is done to the brake shoe to give it robust accuracy and design. This process is necessary to ensure an accurate fit when installed onto the vehicle.

This tool would grind the arc of the shoe to match the drum. The radius is taken from the diameter of the drum and checked, If the radius of the shoe is not right, it could cause uneven braking. Hence, accuracy is vital during this process.

FACILITIES AVAILABLE

Here in Jay & B Tech, we focus on not just core training but ensuring safety and making sure they acquire further developmental skills such as the following:

TECHNICAL TRAINING

The technical training can palely include machine training, fabricating, and complex assembly of the machineries ranging from gigantic heavy machines to tiny machines.

SELF DEVELOPMENT

The relationship between the company and employees is considered symbiotic. The company exhibits signs of growth with the employees acting as pillars of the company. And this is why employees looked into being well-versed in developing inputs and upgrading themselves on a regular basis.

BEHAVIOUR MANAGEMENT

The key element of unity is practising good interpersonal behaviour with fellow workers that will further lead to enhanced productivity. The behaviour of the employees working together is principal as they spend a large volume of their day at work. A digital training program comprising of apt behaviour management skills is necessary for shop floor employees at present.

SAFETY-RELATED TRAINING

Personal Protection Equipment (PPE) is mandatory keeping in mind of every employee’s safety. The right kind of PPE is required with respect to the assigned tasks. It is equally important for an employee to be trained to check and identify if the equipment is outdated or aged, to minimise the risks.

LEADERSHIP SKILLS

Leadership skill as a whole leads to a well-managed and more productive manufacturing company.

Developing the skills amongst the front line supervisors, team leaders and the managers is needed to improve employee safety, productivity and high quality by maximizing the adoption of all team members for the digital training. Foundational skills, organizational skills, technical skills and a customized digital training program is all you need to start learning on the go.

LAB FACILITIES

HOT AIR OVEN

It is used to test for hot shear up to a maximum temperature of 500 degree Celsius

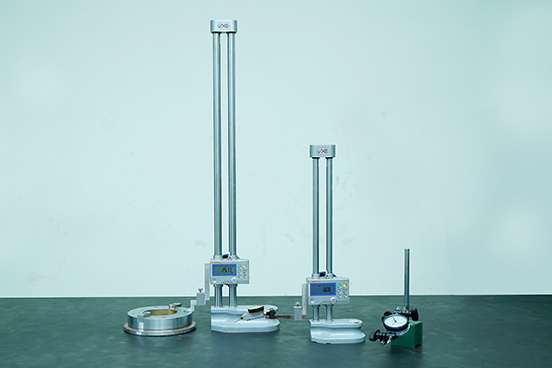

PLUNGER GAUGE

SHOE RADIUS GAUGE

HEIGHT GAUGE

TOOL ROOM FACILITIES

A 7.5 tonne overhead crane facilitates assistance in tool loading, RM storage, tool services and maintenance.

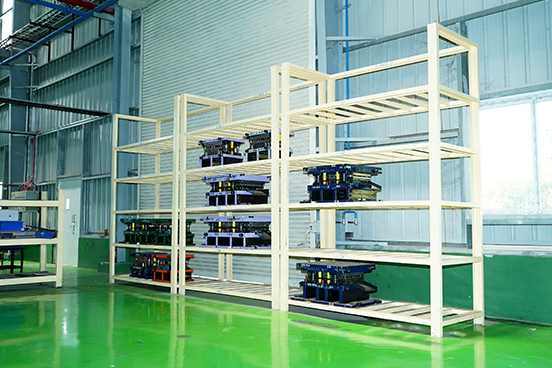

TOOL STORAGE RACK

ADVANTAGES

- HIGHLY AUTOMATED PROCESS

- TOTAL COVERAGE

- CORROSION RESISTANT

- UNIFORMITY

- ON TIME DELIVERY

- HIGHLY PRECISION TECHNOLOGY

- EXPERIENCED PROFESSIONALS